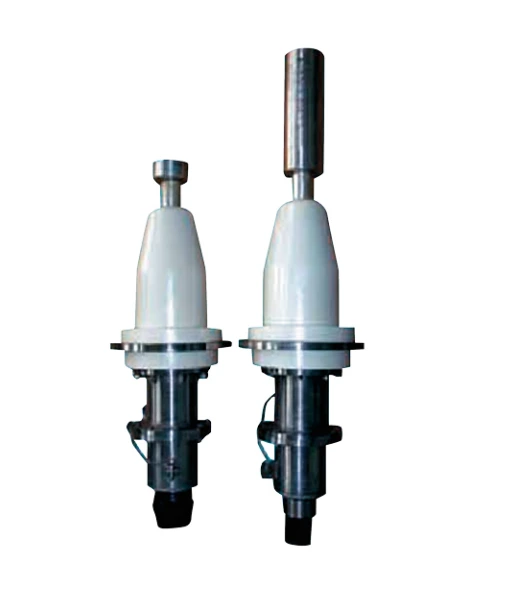

220kV dry type plug GIS terminal

Application:

The terminal is completely dry type structure, the internal is notflled with insulating oil, overcome the stress cone by soaking in theinsulating oil aging, improve the service life of the stress cone, andavoids the terminal leakage phenomenon appeared in the processof running, is both environmental protection and free maintenance.

The combination of the spring pressing device, the application ofcone surface close to the epoxy casing wall, can keep the interfacepressure constant term, overcome the stress cone due to materialaging phenomenon caused by the relaxation, to ensure thelong-term and safe operation of the terminal.

Light weight, small size, compact structure, convenient installationand maintenance.

All the insulation parts are made of the factory, and the epoxycasing is embedded in the high pressure metal shield electrode.Therubber stress cone is used to import the high elastic liquid siliconerubber, and the structure shape of the stress cone product is opti-mized.

Model No.:220kV dry type plug GIS terminal

Material:Organic Insulation

Brand:KINGYEAR

Standard:IEC

Place of Origin:China

Package:Exported Package

Range of Application:Cable

Terms of Payment: L/C, T/T, D/P, PayPal, Western Union, Small-amount payment

Certification:ISO,CE and other certifications.

Production Capacity:3000piece/week

The terminal is completely dry type structure, the internal is notflled with insulating oil, overcome the stress cone by soaking in theinsulating oil aging, improve the service life of the stress cone, andavoids the terminal leakage phenomenon appeared in the processof running, is both environmental protection and free maintenance.

The combination of the spring pressing device, the application ofcone surface close to the epoxy casing wall, can keep the interfacepressure constant term, overcome the stress cone due to materialaging phenomenon caused by the relaxation, to ensure thelong-term and safe operation of the terminal.

Light weight, small size, compact structure, convenient installationand maintenance.

All the insulation parts are made of the factory, and the epoxycasing is embedded in the high pressure metal shield electrode.Therubber stress cone is used to import the high elastic liquid siliconerubber, and the structure shape of the stress cone product is opti-mized.

The main insulation parts have been tested in the factory accordingto the standard.

GB/T 18890.3-2015 Power cables with cross-linked polyethyleneinsulation and their accessories for rated voltage of 220 kV(Um=252kV).Part 3: Accessories

EC62067-2011 Power cables with extruded insulation and theiraccessories for rated voltages above 150 kV (Um = 170 kV) up to 500kV (Um=550 kV).Test methods and requirements

GB/T 22381-2008 Cable connections for gas-insulated metal-en-closed switchgear for rated voltages of 72.5 kV and above.Fluid-flled and extruded insulation power cables. Fluid-flled anddry type cable-terminations

EC 62271-209-2007 High-voltage switchgear and controlgear. Part209:Cable connections for gas-insulated metal-enclosed switchgearfor rated voltages above 52 kV, Fluid-flled and extruded insulationcables.Fluid-flled and dry-type cable-terminations

Specifications

Advantage

FAQ