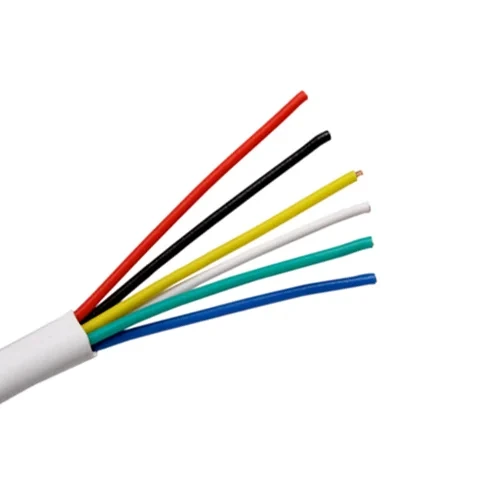

LiYY Control Cable 300/300V

Application:

The LiYY cables are for indoor signal and data transmission in indoor industrial applications such as computer systems, measuring equipment and process control devices in offices, laboratories and production lines under low mechanical and tensile stress. This range is particularly well suited to applications requiring a cable with a small overall diameter.

Model No.:LiYY Controal Cable

Voltage:300/500V

Material:Copper

Brand:KINGYEAR

Standard:IEC/GBT/VDE/ASTM/BS/EN

Place of Origin:China

Package:Exported Wooden Drum

Range of Application:Control Cable

Terms of Payment: L/C, T/T, D/P, PayPal, Western Union, Small-amount payment

Certification:ISO,CE and other certifications.

Production Capacity:30000m/week

LiYY cables with a cross-section of up to 0.14mm2 have a voltage rating of 350V. Larger cross-sections have a voltage rating of 500V. They have an operating range from -40oC to +80oC in fixed installations and -5oC to +50oC when flexed.

LiYY cables are also available up to 36 cores as standard. For more information and larger core sizes, please refer to the technical specification or speak to our sales team.

This cable can be used for signal transmission between electronic devices, in computer systems or process control units.

Voltage Rating Uo/U

250/250V

Conductor

Class 5 Fine Stranded Bare Copper

Insulation

PVC (Polyvinyl chloride)

Outer Sheath

PVC (Polyvinyl chloride)

KINGYEAR from 2013-2018 are mainly for domestic trading and processing to some export trading companies. The average sales amount are about RMB 320,000,000 per year. For cables oversea market, From last may till now we have expanded our market to Bolivia, Peru, Dominican, Philippines, Vietnam, Thailand, Iraq, Mongolia, Indonesia and some Africa country. With total sales amount over USD10,000,000.

Specifications

AAC - BS 215

| Conductor | Insulation | Shield | Drain | Braid | Jacket | Max. cond. resistance (Ω/km,20ºC,DC) |

|||||

| AWG | Construction No./mm |

DIA(mm) | No. of cores | thickness (mm) |

O.D (mm) |

Material | ConstructionNo./mm | ConstructionNo./mm | thickness(mm) | O.D (mm) |

|

| 30 | 7/0.1 | 0.3 | 2 | 0.25 | 0.8 | Al-mylar | 7/0.1 | 16/4/0.1 | 0.76 | 3.8 | 381 |

| 3 | 0.25 | 0.8 | Al-mylar | 16/4/0.1 | 0.76 | 3.9 | |||||

| 4 | 0.25 | 0.8 | Al-mylar | 16/5/0.1 | 0.76 | 4.2 | |||||

| 5 | 0.25 | 0.8 | Al-mylar | 16/5/0.1 | 0.76 | 4.4 | |||||

| 6 | 0.25 | 0.8 | Al-mylar | 16/6/0.1 | 0.76 | 4.6 | |||||

| 7 | 0.25 | 0.8 | Al-mylar | 16/6/0.1 | 0.76 | 4.6 | |||||

| 8 | 0.25 | 0.8 | Al-mylar | 16/7/0.1 | 0.76 | 4.9 | |||||

| 9 | 0.25 | 0.8 | Al-mylar | 16/7/0.1 | 0.76 | 5.2 | |||||

| 10 | 0.25 | 0.8 | Al-mylar | 16/7/0.1 | 0.76 | 5.5 | |||||

Advantage

FAQ